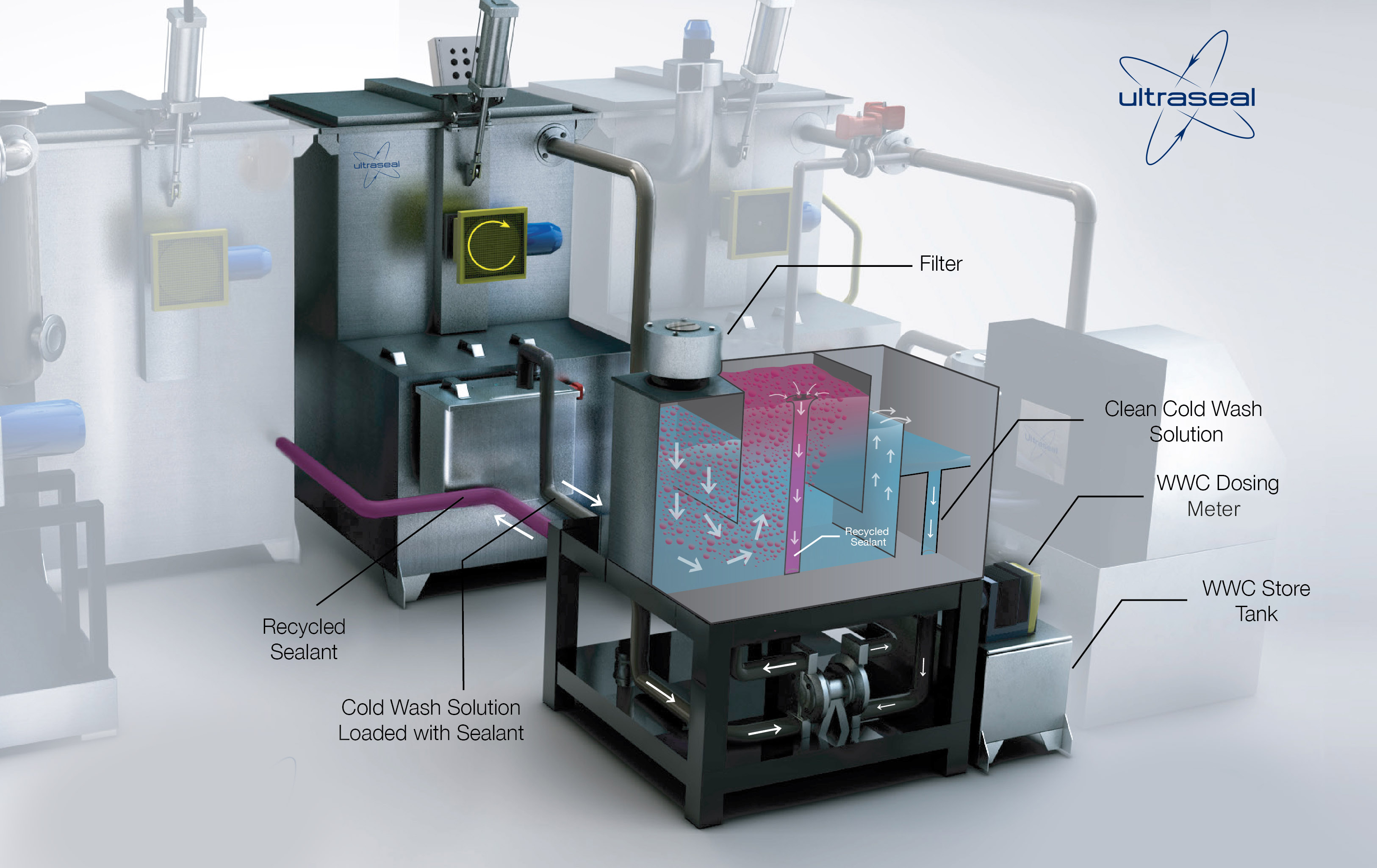

Fully automated impregnation systems

Minimising operator involvement to improve safety, consistency and production costs

The use of automated production equipment significantly reduces production and labour costs and minimises operator involvement, ensuring output consistency, quality and health & safety.

Over the last two decades, we have developed unrivalled expertise in the design, development and manufacture of automated impregnation equipment and systems to ensure we can meet your production component processing requirements, including:

- Robotic component loading and processing

- Automated conveying and product handling solutions

- Custom engineered automated processing plant

- Complete production line integration

After understanding your needs and thorough planning, each of these systems is developed from our best-in-class modular hardware and software base to a customer’s needs. The automation equipment is integrated as an entire system into your existing production equipment, or can be setup as an independent system.

With in-house design, manufacture, assembly and testing to high quality standards we ensure that factory acceptance tests are carried out in a comprehensive manner prior to customer delivery.